The Past is Present: Concrete Tanks and Eggs Evoke Historic Winemaking

In wine, it seems that everything old is new: Organic grape growing, dry farming without irrigation, wild yeasts, cloudy Pet-Nat bubbly and concrete tanks.

Dating back into the early 1900s, concrete tanks were widely used in winemaking. The often-giant tanks were poured on site, then lined with an inert material and used for both fermenting and aging wines. They were long-lasting and sanitary, and unlike wooden vats, didn’t harbor molds and bacteria that could compromise the wine. They also provided thermal stability, helping reduce temperature variations during winemaking. Some people even think egg-shaped tanks have mystic properties. In some regions like Northern Italy and the Republic of Georgia, winemakers even used ceramic amphorae like those from classic times, usually buried in the ground to keep them cool and protect against breakage. During the mid-20th century the development of stainless tanks seemed to render concrete obsolete, although many of the old tanks remained in use in many wine regions.

CONCRETE EGGS

Jump 150 years ahead to 2019: Concrete tanks are everywhere. Large egg-shaped tanks have gripped the attention of both winemakers and visitors. That may be partly winemakers’ relentless drive to make better wine, but most admit that visual appeal has its place. “The eggs look so cool,” joked Rebekah Wineburg, the winemaker at Quintessa, who has several in different sizes.

Bruce Cakebread’s eponymous family winery is installing 12 additional eggs in its new visitor center after about four years of working with eggs,” joining many other wineries that have tried out the provocative vessels.

Cakebread has been fermenting Sauvignon blanc and aging Chardonnay with a concrete egg for the last four years. Winemaker Stephanie Jacobs said that concrete allows for micro-ox (introducing a tiny amount of oxygen) or aging similar to a barrel, however without the contribution of oak aromas and flavors. It regulates temperature more evenly. Additonally, “The convex shape of the egg encourages lees suspension.”

Smaller and slimmer amphorae-shaped versions also catch guests’ eyes.

CONCRETE TANKS, CONES AND CUBES

Box-like tanks are also being installed once again, but they’re typically smaller than the gargantuan tanks once used. Most are built-in factories using sophisticated technology rather than poured into forms created on site.  Smaller “cubes” hold the wine of four barrels and can be stacked and moved about, giving the benefits of small containers with greater space efficiency, more straightforward cleaning and the ad- vantages of oak but no oak flavors.

Smaller “cubes” hold the wine of four barrels and can be stacked and moved about, giving the benefits of small containers with greater space efficiency, more straightforward cleaning and the ad- vantages of oak but no oak flavors.

And cousins of popular oak tanks with truncated cone shape are often paired with concrete tanks of similar format to provide flexibility for winemakers – offering a cool talking point and for images as well.

Winemaker Wineburg at Quintessa recently installed 22 high-tech 1,400- gallon rectangular concrete tanks based on her experience with old concrete vats and eggs. Used for white wines, this is likely the largest such installation in Napa Valley. They replaced large wood tanks, but the winery also has some older-generation concrete tanks made in France sans the cooling coils or the inert surface.

Aesthetics aside, the thick concrete walls buffer the contents from rapid temperature changes, and the cooling coils ensure tight temperature control. A significant advantage over wood is that it’s easier to keep concrete clean, unlike the wood staves and heads that can harbor con- taminants. Aside from the water used to clean them, wood tanks must be kept filled with water when they don’t contain wine to maintain them. “The amount of water needed is horrific,” said Wineburg, noting California’s perpetual water shortages.

Weinburg does find some unique impact from the tank’s material, which she compares with stainless steel and concrete tanks and oak and acacia barrels. However, it’s not bad, just different. “We see softer tannins than with stainless,” she said.

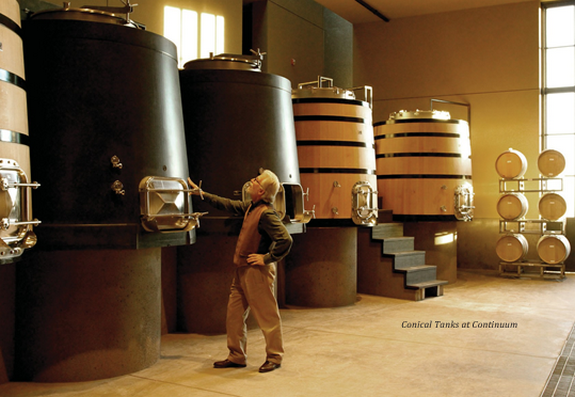

Though Quintessa opted for rectangular tanks, the most popular shape is the truncated cones holding 1070 gallons used at such wineries as Continuum and St. Supéry. They mirror the most popular oak tanks, providing an appealing visual contrast. Next in popularity come eggs and NuBarrel “cubes.”

Tim Mondavi of Continuum is a big fan of concrete tanks. He has matching oak and concrete tanks as well as stainless steel used for blending – and of course, oak barrels to age the winery’s iconic red wine. “Stainless steel retains freshness and brightness, and they’re simpler to maintain. They also chill much faster.” Mondavi finds that the wines are all tighter and more austere in large oak tanks with breadth and depth. “Concrete gives more minerality and helps the tannins evolve more and become more tender.” He added, “Concrete is more ‘feminizing’.”

At St. Supéry, winemaker Michael Scholz uses four conical concrete tanks for white wines. “They give a textured feel and minerality” and as at other wineries, create subtle tastes and textures useful in blending the optimum wine.

Frog’s Leap uses the cubes, which hold four times as much wine as a barrel, for aging Zinfandel. The winery also has an egg used for fermenting and aging a single-vineyard Sauvignon Blanc. Rory Williams said that egg gives the wine body, but it also is expensive and uses space inefficiently. Nevertheless, they placed it prominently in spaces visitors see. Rory’s father John Williams suggested the NuBarrels as he felt that new oak overpowered the Zinfandel and they only use 10 to 15 percent new oak. The winery now has 80 of the cubes.

“The wine is fresh and light. It’s the depth of new oak barrels without the oak flavor.”

WHAT’S AHEAD

One property of concrete is much debated – whether it’s porous to air. Some claim it allows very subtle “micro-oxygenation,” but other winemakers and researchers dispute that.

The most popular tanks are built by Sonoma Cast Stone in Petaluma using layers of concrete, some mixed with fiber- glass for strength, and contain reinforcing and integral tubing for heating or cooling. Their interior surface is so smooth that they don’t need a coating and inert enough to have little effect on the wine’s chemistry after initial neutralizing of the slightly alkali material with tannic acid.

As for cost, stainless steel is the least expensive with wood and concrete comparable in initial investment but the concrete is more sustainable, perhaps last up to 40 years, noted James W. Herwatt, CEO of Sonoma Cast Stone.

Other concrete tanks are made by Vino Vessel, while Vital Vessels fires ceramic versions in a giant kiln. At least one winery created new tanks built into the winery. At Ovid, the innovative tanks have ports outside the winery for easy loading of grapes.

And the eggs have a New Age attraction to some vintners such as at Biodynamic grapegrower Quintessa that is attuned to phases of the moon and psychic phenomena.

Whether that’s true or not, concrete tanks are finding their way into the main- stream of winemaking. They’re certainly a new old tool involved in the eternal wine- makers quest to make better wine.

FOR MORE INFORMATION:

Cakebread Cellars // www.cakebread.com

Continuum Estate // www.continuumestate.com

Frog’s Leap Winery // www.frogsleap.com

Ovid // www.ovidnapavalley.com

St. Supéry Estate Vineyards & Winery // www.stsupery.com

Quintessa // www.quintessa.com

Sonoma Cast Stone // www.sonomastone.com

Vino Vessel // www.vinovessel.com

Vital Vessels // www.vitalvessels.com

Article By: Paul Franson